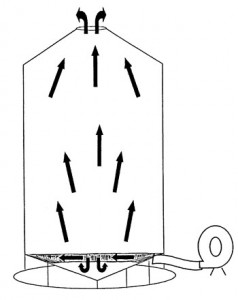

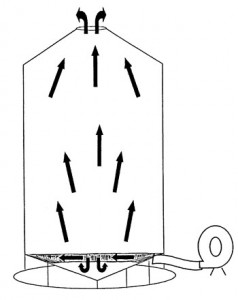

Diagram of airflow through a silo

Benefits of a grain aeration system

- A crop can be stripped with some green patches in it

- A crop can be stripped at higher moisture content without the risk of spoiling

- Start harvest earlier in the season, earlier in the day and continue later into the night

- If a storm was coming you could strip it with higher moisture content, getting it into the silos, knowing you could dry it later and not lose your crop

- Stripping grain with higher moisture content assists in the cooling cycle, it is the same principal as an evaporative air conditioner, but in this case the grain is the wet filter

- Cooled grain has higher germination rates

- Less attractive to weevils.

I have been in the silo sealing trade for 30 years now and I reckon this is the best dryer/aerator ever introduced into the on-farm storage market. No other aerator in the market can dry grain! They can cool and even out moisture between a dry load and a moist one in a silo, but cannot dry grain. The system has been tested and been in use by farmers for 16 years now.

250 ltr/sec fan

I cover a large slice of the grain growing are in the Eastern States, from Ceduna, South Australia, to Emerald, Queensland. This is the best machine I have ever come across. The only dryer that comes close is a Kotzur drying silo, which starts at $60,000 each.

1000 ltr/sec 2.2 kw elec fan

Bigger 3hp fans available

2000 litres per second

2500 litres per second

Powered by a 3hp electric motor or 6.0hp Yamaha ($400 extra); the air is blown by a huge fan through 150m (6”) ducting on the silo. Then distributed by a device called a plenum; which is an open upside down ‘V’, 2.4m (8 feet) long and 300mm (1 foot) across at the open side. It is fixed across the centre of the silo cone and attached to each side (see attached diagram of the air flow). There are no holes in the ‘V’ so it can be used to dry all seed types; canola, lentils, grains etc.

When drying stored grain we use ambient air and pump it through the grain and it dries surprisingly quickly during the warmer periods of the day (depending on the weather conditions). If they can get it off and into the silo and then dry it they will get much better returns. Wheat and barley were generally harvested at 12-13% moisture, our system allows stripping at 16-17%. Our system works the same as an evaporator air conditioner although in this case the grain is the wet filter. To cool stored grain the fan should be operated during the coolest periods of the night to achieve maximum cooling performance. An automatic controller is available to select only the coldest conditions when cooling or the warmest conditions when drying.

110 ltr/sec fan

Air runs through ducts from a fan to the base of the silo and flows upwards through the grain, taking the moisture and heat with it. It does depend on how big the silo is, but a normal system would operate in 2 silos at once.

The dryer/aerator will fit every cone bottom silo. Flat bottom silos and sheds need different air distribution ducts.

Features

- Strong, pressed steel casing

- Durable, hot dipped galvanised finish

- Lightweight and manoeuverable

- Beautifully balanced for no vibration (electric)

- One fan can be moved to other sites with plenum fitted (saves on multiple blowers)

- Diesel fired heaters available for faster drying

- Competitive prices and a 12 month warranty

Automatic Temperature / Humidity Controller

Developed and built by us for use with all drying/aeration systems.

Designed to plug straight into single-phase powered fans, and can be used to operate 3-phase fans through a relay switch.

We have sold 100’s of these over 15 years and nothing compares in value, with other temp/humidity controllers costing $10,000 plus installation.

- Change from drying to aeration cycle with the flick of a switch

- Dials adjusts temp/humidity settings to suit your location

- Built-in timer to log hours run by fans when you are not there

- Small enough to be delivered to you by Australia Post

- 12 month warranty

$2,800 inc. GST